Suspension and its adjustments have an big impact to motorcycles control and runnability. Suspension consists of springs and shock absorbers. Springs are there to damb the power result from bumps, accelerates and brakes, as well from curve coming centrifugal forces. Shock absorber is there to slow down movement of the spring, when spring doesn’t get to compressed and come back in full force. That way the tyre stays stick to the track as good as possible. Actually springs and shock absorbers are there to do two things, get motorcycle moving forward as smoothly as possible and prevent tyres break away from track surface. Suspension adjustments can improve or weaken its functionality.

Sprung and Unsprung Mass

Motorcycle mass could divide sprung and unsprung mass. By sprung mass I mean frame, fuel tank, engine etc. By unsprung mass I mean brakes and rims etc. When driving for example to bump, tyre rise upwards compressing springs, which again pursue to rise frame. Motorcycles own mass drag rising and rising movement strenght depends on springs stiffness and tyre, rim and other unsprunged parts mass. So the smaller unsprunged mass is commensurate to sprunged, the better motorcycle can resist tyre movements and stays better in track surface. Tyre loosening to track depends greatly which is ratio of sprunged and unsprunged mass. Example in MotoGp there are aspired to get unsprunged mass as low as possible, by making expensive carbon fiber back forks and rims. In series-produced those are so far too expensive.

Progressivity

Progressive suspension means suspension, which chances all along stiffer when tyre boundingmovement increases. In that kind of suspension tyre remains in track surface remarkably strictly. Progressivity prevent spring bottoming in bounding, when driving for example to big bumbs. Telescopefork progressivity is commonly achieved by progressive spring. Spring spiral is thicker in the other end of spring. Rarer way is to put two linear springs, which spring stiffness is unequal between each other.

Rearspring progressivity can be achieved by many ways. One simple way is to install linear spring-shock absorber element in sloped angle to rearfork so that upper fastening point is more front than lower fastening point. If spring-shock absorber element is located on an right angle towards to rearfork, then is spring movement range directly comparable to reartyre movement range. In sloped spring-shock absorber element, spring compress in the beginning of the tyre movement only a little, but when tyre movement grow, spring and swingarm angle chances to greater and in the same time spring movement and stiffness increases.

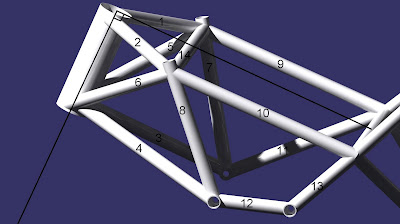

Progressivity could be achieved also by progressive spring or by putting two spring stiffness unequal springs. These options aren’t very common in this day track made motorcycles. Half the time progressivity is achieved by variable ratio levermechanism also known as linkage. This kind of structure gets spring progressivity work just like designer wants. This is also cheaper to achieve, than for example by using progressive spring.

Suspension Parts For The Meantime

Before I told, that we bought a crashed year 2004 Suzuki GSX-R 750 cc motorcycle from damaged vehicle center. Shock absorbers were quite good guality in Suzuki, so we ended up to use those in our project. In front there was telescopic fork, which inner tubes were lower so it was so-called upside-down front fork. Upside-down fork benefit to combared to the right way fork is notably stiffer structure. In front fork there was also adjustments for shock absorption bump- and rebound movement absorption power and for springs pre-load. These adjustments are actually necessary if the goal is to get best possible suspension for track. Rear shock absorber spring stiffness and shock absorption could also be adjust.

Parts which we get from Suzuki aren’t under no circumstance best suited to our project. Example in WP or Öhlins shock absorbers is some more better adjustments and those are also lighter,which again degrease unsprung mass and improve drivability. Later idea is to chance shock absorbers, or actually as soon as budget allows it.

Next time my intention is to tell, which kind suspension solutions we ended up in our project.